In a time marked by significant transformations, it has become crucial for businesses to implement four key strategies for managing supply chain operations to maintain resilience and competitiveness.

As organizations encounter challenges such as the aftermath of globalization, disruptions in supply chains, and evolving labor dynamics, leaders are required to embrace innovative methods to guarantee operational efficiency.

Traditional approaches may no longer suffice, prompting experts to advise supply chain managers to reevaluate their strategies in preparation for a more uncertain future.

Grasping the Evolving Landscape of Supply Chain Management

The field of supply chain management is undergoing rapid changes. In the past, companies depended on algorithm-driven inventory management and straightforward supply chain frameworks.

However, the rising occurrence of global disruptions has compelled a transition towards more adaptable and proactive strategies. Industry specialists highlight the necessity of a dynamic approach that harmonizes risk management with operational efficiency.

Consequently, supply chain managers should contemplate these four vital strategies for 2025 and beyond.

-

Categorize Inventory and SKUs

A highly effective method to improve supply chain flexibility is through the categorization of inventory and SKUs.

By classifying products according to their value, turnover rate, and necessity, organizations can enhance inventory management and minimize waste.

The Significance of SKU Analysis

SKU analysis is essential for maintaining the agility of supply chains. A strategically prioritized inventory portfolio enables organizations to swiftly adapt to market changes.

As demonstrated by FDH Aero, an aerospace parts distributor, purchasing parts in bulk without evaluating their actual value can lead to significant financial losses.

By categorizing inventory according to its relevance and demand, companies can enhance their purchasing strategies.

Enhanced Warehouse Organization

The implementation of SKU stratification also contributes to improved warehouse organization. Items with high turnover rates should be located near shipping areas, while those that are less frequently utilized can be stored further away.

This organized method not only accelerates order fulfillment but also reduces storage inefficiencies.

-

Balancing Just-in-Time and Just-in-Case Strategies

Traditionally, just-in-time (JIT) inventory management has been favored for its ability to lower carrying costs. However, the unpredictability of the current supply chain landscape has exposed the vulnerabilities inherent in this approach.

While JIT effectively reduces surplus inventory, it also exposes businesses to potential disruptions in the supply chain.

The Transition to Buffer Stock

Numerous organizations have adopted a just-in-case (JIC) strategy, which involves preemptively stocking essential products to mitigate the impact of unforeseen delays.

This strategy gained significant importance during the COVID-19 pandemic, as businesses faced prolonged lead times for vital materials.

Striking the Right Equilibrium

Finding the ideal balance between just-in-time (JIT) and JIC strategies necessitates a thorough evaluation of product significance and market dynamics.

For instance, FDH Aero prioritizes maintaining buffer stock for high-value items while minimizing the accumulation of low-demand components.

This strategic approach ensures efficient resource allocation without incurring unnecessary financial strain.

-

Leveraging AI for Demand Planning and Forecasting

Artificial intelligence (AI) is transforming supply chain management by improving demand planning and forecasting capabilities.

Conventional forecasting methods typically depend on historical data, which may not reliably predict future disruptions. In contrast, AI-driven tools provide real-time insights and greater adaptability.

Enhancing Prediction Accuracy

Forecasting driven by artificial intelligence significantly boosts prediction accuracy by examining extensive datasets, which encompass market trends, consumer behavior, and external influences like geopolitical developments.

R. Ravi, a professor at Carnegie Mellon University, notes that AI’s capability to enhance prediction models renders it an invaluable resource for supply chain managers.

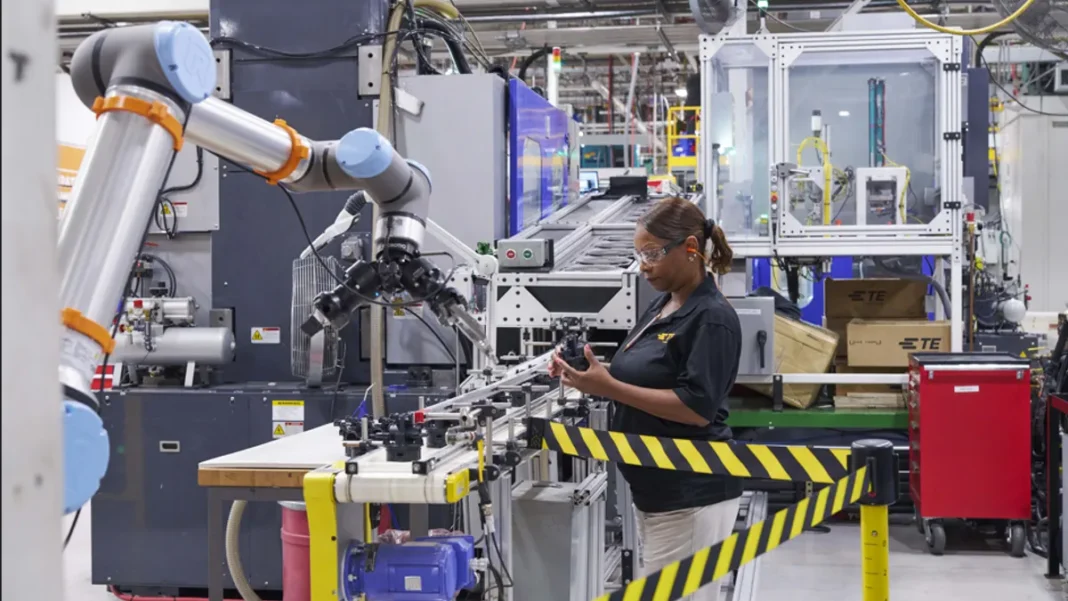

Generative AI in Manufacturing

Artificial intelligence is also advancing manufacturing processes. AI-enabled predictive maintenance empowers companies to foresee equipment malfunctions before they happen.

By utilizing AI to analyze sensor data, organizations can avert operational interruptions and lower maintenance expenses.

Strategic AI Implementation

Despite its promising capabilities, the implementation of AI must be approached with strategy. Organizations should ensure that AI solutions effectively tackle genuine operational issues rather than being adopted merely for the sake of technological advancement.

Leaders ought to assess how AI can improve current processes and incorporate it accordingly.

-

Implement a Zero-Base Exercise

Reevaluating supply chain strategies from the foundation is essential for achieving long-term success. A zero-base exercise entails assessing supply chain operations without depending on past data or preconceived notions.

This method fosters innovative solutions and enables businesses to create resilient supply chains.

The Importance of Zero-Basing

Numerous supply chain leaders often find themselves addressing immediate issues rather than engaging in proactive future planning.

A zero-base exercise redirects attention from temporary solutions to enduring sustainability.

By scrutinizing current processes and investigating new approaches, organizations can formulate stronger supply chain strategies.

Enhancing Warehouse Management and Budget Distribution

Zero-basing can also be utilized in warehouse management and budget distribution. Rather than making gradual enhancements, organizations can overhaul their operations to optimize efficiency.

This may include adopting new tracking technologies or reorganizing supply chain workflows.

A Strategic Evolution in Supply Chain Management

Experts indicate that supply chain management is evolving from a tactical role to a strategic discipline.

The capacity to foresee and address disruptions will be pivotal for success in the years ahead.

Companies that adopt zero-base exercises will be more adept at navigating uncertainties and achieving operational excellence.

Expert Editorial Comment

As the supply chain environment continues to transform, it is crucial for businesses seeking to maintain their competitive edge to implement four key strategies for managing supply chain operations.

By categorizing inventory, finding the right balance between Just-In-Time (JIT) and Just-In-Case (JIC) methodologies, utilizing AI-enhanced forecasting, and performing zero-based assessments, supply chain managers can improve both efficiency and flexibility.

In the years leading up to 2025 and beyond, a company’s success will hinge on its capacity to adapt to change, focus on strategic planning, and effectively harness technology.